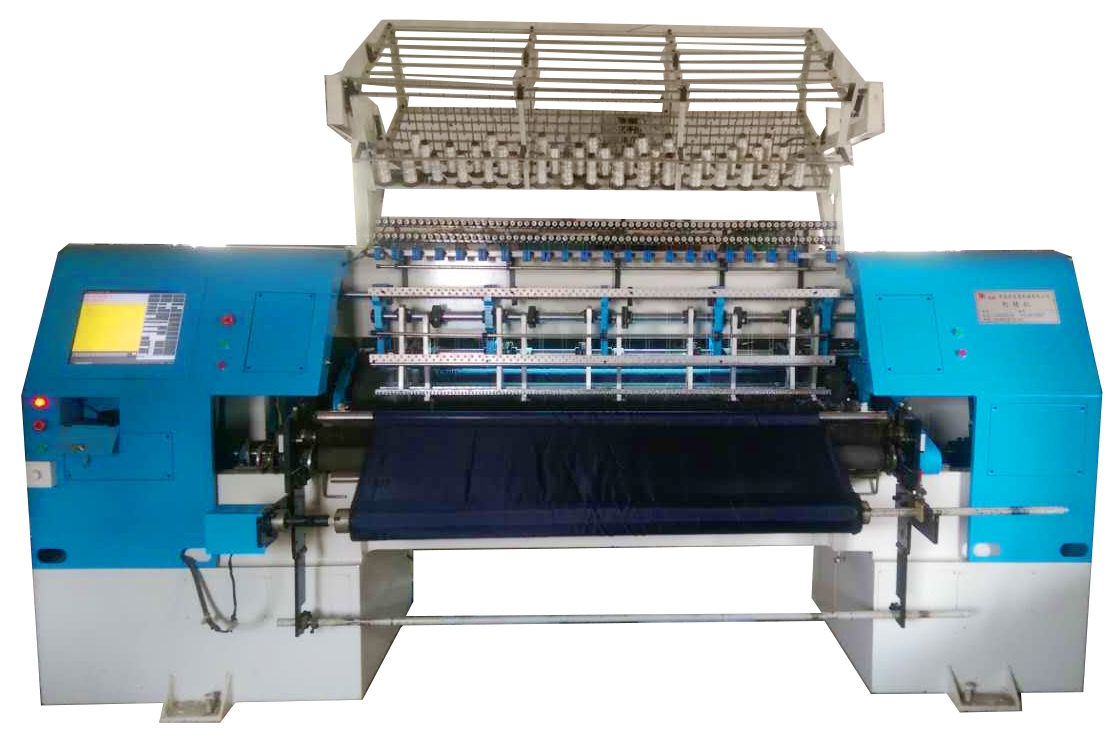

Quilting Machine for Mattress Manufacturing Industry for Making Premium Range

The chain stitch quilting machine is specially designed for the mattress manufacturing industry, offering speed, strength, and consistent stitch quality to meet the demands of high-volume production. Built to handle heavy fabrics and thick mattress cores, these machines streamline the quilting process while ensuring durable, attractive finishes.

This quilting machine is the ideal choice for large-scale production, built to handle heavy workloads while delivering precise, attractive stitching across a wide range of patterns. Engineered for mattress manufacturing, it works reliably on foam up to 80 mm thick, including PU foam commonly used in mattresses and toppers.

Robust performance and capacity – Heavy-duty frame and industrial-grade components keep stitching consistent through long production runs, reducing downtime and maintenance. – High-speed operation increases throughput without sacrificing stitch quality, making it a cost-effective solution for larger factories.

Versatile patterning for tailored designs – A flexible pattern library lets operators select from many quilting styles—straight lines, waves, channel quilting, and complex decorative motifs—so you can match customer preferences or brand aesthetics. – Programmable pattern changes enable quick switching between designs, supporting mixed batches or custom orders with minimal setup time.

Foam-friendly handling up to 80 mm – Specifically calibrated to feed and stitch through up to 80 mm of PU foam, the machine ensures even stitch tension and avoids fabric shifting or foam compression that can ruin the finish. – Adjustable presser and feed settings allow fine-tuning for different foam densities and composite layers, preserving mattress integrity while achieving neat, durable quilting.

Operator ease and production control – Intuitive controls and touch-screen interfaces simplify pattern selection, speed adjustment, and diagnostics, lowering the learning curve for new operators. – Integrated sensors and automatic thread break detection minimize waste and speed recovery when issues occur.

Durability and serviceability – Modular design makes routine servicing and part replacement straightforward, keeping the machine running and easy to maintain. – Built from corrosion-resistant materials and engineered for continuous use, it stands up to the demands of high-volume mattress lines.

Use cases and benefits – Mattress manufacturers producing memory foam, hybrid, or PU-foam mattresses will find this machine particularly effective for delivering consistent quilting depth and pattern clarity. – Suitable for factories shifting between product lines, it supports rapid changeovers and maintains visual quality across different foam thicknesses.

In short, this quilting machine combines industrial strength, pattern flexibility, and foam-specific handling to meet the needs of large-scale mattress production, delivering reliable output and professional finishes on up to 80 mm PU foam.

This advanced looper quilting machine adopted refined Japanese engineering with user-friendly features to make quilting faster, cleaner, and more creative. Its versatile design supports a wide range of quilting patterns—from classic meanders and stippling to intricate geometric and floral quilting designs—so users can easily match the stitch style to each project. Built-in tack and jump quilting functions let operators anchor sections and traverse gaps smoothly, reducing thread breaks and saving time when moving between pattern areas.

Controls are intuitive, with clear settings for stitch length, tension, and pattern selection, so both experienced quilters and newcomers can get consistent results with minimal setup. The machine’s precise looper system produces even stitch formation across thick batting and multiple fabric layers, while robust construction ensures long-term stability and low maintenance.

Practical features like quick-change needle and looper access, adjustable presser and roller pressure, and handy storage for tools keep workflow uninterrupted. Whether producing different style of mattress covers, this looper quilting machine delivers reliable performance, flexible design options, and efficient handling of tack and jump quilting tasks—bringing professional-quality finishes to every project.